When Demand Outstrips Supply –

Keeping Up with the Thirst

We are having a good problem at Hess Brewing and that is that we are running through the beer faster than expected and almost faster than we can keep up . The days of single-brew days may be nearly behind us; perhaps the days of brewing just 50 gallons at a time are almost in the rear view mirror. Not saying we are going non-nano, but running out of beer is no fun. For now, the work around is DOUBLE BREW DAYS.

We had not attempted it yet on the system until recently, even though with the 4th kettle - the whirlpool tank, the system was designed to be able to do so efficiently. However, the luxurious lackadaisical days of single brews must give way to progress. And you can’t stop progress as Muriel’s dad said.

Timeline management and adherence to it would keep this day reasonable. I spent about 2 hours going over the timeline for the brewday. Extensive note taking has allowed me to know how long it takes to mill, to fill, to transfer, etc. Now the trick was to integrate the two brews such that we would be working on brew #2 while finishing up brew #1. Did it matter which came first (not the chicken or the egg, man, the Stout or the Vienna)? To my amazement, it mattered not, despite one having a 2:15 boil and the other just 70 minutes. Therefore the Stout was up first. Want to have clear head for that brew. Lots ‘o stuff going on in ole duder's head for that one...

For logging our beers on brewday, we are using a sheet from Mosher’s Radical Brewing. I’ve taken this sheet and “radically” tweaked it to be relevant for our brewery. For big picture tracking, we use our own Excel sheet to schedule the events through the brew day. At any time, we know exactly where we are in the process for each beer, to the minute.

Grazias in the Hopper

Grazias in the Hopper

Up first, milling. Greg and I rolled in at 5 am, loaded up with Yerba-Mate tea and breakfast burritos. Having pre-measured the base and two of the specialty grains and loaded the hopper the night before - Greg flipped the ONOFF switch and started measuring out and milling the rest of the grist. I worked on filling the mash tun’s strike water and lining up the pumps and hoses.

Over the course of the next 10 hours, the ‘Will Work for Beer’ Hess Crew rolled in, rolled up their sleeves and got to work. Brenden and Tim came in, followed by Frank and Dustin. Without this crew of tireless, selfless beer lovers working together, the two-brew day couldn’t have happened. Event after event came and went – the schedule was holding true. Kettles cleaned, hoses rinsed, floors mopped. Switch over, from knocking out the Stout to lautering the Grazias happened at 1139! Arg, we were 4 minutes behind… :)

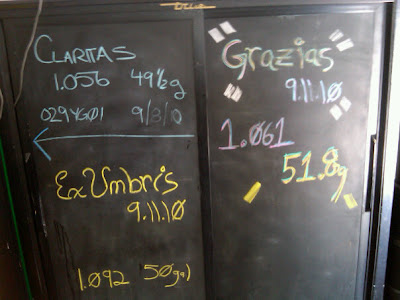

We were all stoked when we finished filling the Ex into the first fermenter. As we went to document what we had on the chalkboard, we found that batch to batch, we were right on the money – notice Greg writing directly over the previous batch’s chalkboard notes:

That looks like 50 gallons at 1.092...again!

That looks like 50 gallons at 1.092...again!

The results of our first two-fer.

We have since done one other double batch day –on 9/29 we did our twin hybrids – the Alt and the Kolsch. With 90 minute boils, this day took about 9 hours. They both ferment out at the same temp, so they are together in our lone double GDM (glass door merchandiser), and because they will be in there for a bit together and b/c we need more beer(!), we actually did just brew a single batch of IPA today for our single GDM.

Brewday could be even faster if it weren’t for our ground water issues. Ground water in SD is now about 80, so chilling without any glycol in the brewery is a challenge. What we’ve come up with though is awesome in it’s MacGyver-ness and its effectiveness, but it adds over an hour and a half to our double day. The reason for this is that we are using our hot liquor tank as the post-chiller, therefore cannot have it employed for providing hot liquor to the top of the mash tun.

Here’s what we’re doing: After sending the wort to the WP kettle and letting it settle out for 20 minute or so, we hook up our custom March pump to the outlet of the WP. From the pump, ¾” tubing connects to the WortIn of the Therminator. Hose water provides the cooling – outlet wort temps are probably in the low 100’s at this point. From here, we run the WortOut to our convoluted copper coil that is in our HLT. We have moved the HLT onto the spot formerly occupied by the Boil Kettle. The last thing the HLT had going through it was 170* sparge water and it has been immersed in the HLT for some 3 hours. No sanitation issues here. The HLT is filled with ICE (up to covering the coil) and the wort exits the coil as chilled as in the low 50’s. (BTW - when we get around to doing a lager, no problem getting to pitch temps.) Stirring the ice in the HLT keeps the coil cold and the system is so efficient we can knock out at just over 2 gpm – 25 minutes for the whole batch from 200* to 65* no problem. We have the pump on full bore and the only valve the whole way through – the outlet on the WP kettle – is wide open. If the convoluted copper were ¾” instead of ½”, we could likely get it done quite a bit quicker.

The HLT being used as part of the cooling loop though prevents us from being able to get that second batch going as soon as we like. If we can figure out another way or the ground water gets cooler, allowing the Therminator to do all the work, I can see double days taking maybe 8 hours all in.

Meanwhile, as long as the Brew Crew shows up, and so that we can keep up with demand, I envision always brewing twofers with the addition of another double-door GDM. Or maybe a 10 bbl brewhouse with eight 20 bbl fermenters…well, someday anyway….